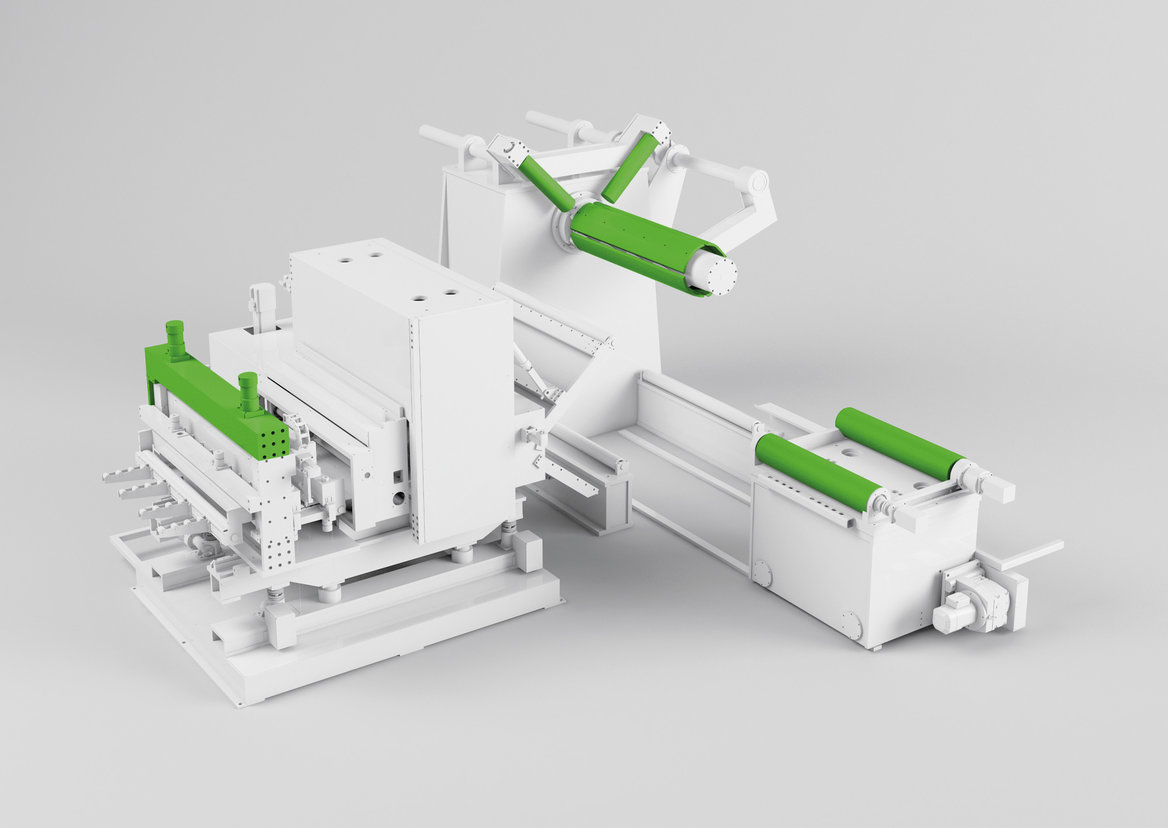

They are used as feeders on presses that have their own control system and can therefore also be retrofitted. They are also used in cut-to-length lines on which metal sheets are cut to specific dimensions.

| Type | Strip width | Strip thickness | Cross-section | Material | Height adjustment | Feed accuracy | No. of strokes | pilote lifty | ||

|---|---|---|---|---|---|---|---|---|---|---|

| min. mm | max. | min. mm | max. | max. mm2 | max. mm | +/- mm | +/- mm | max./min | ||

| WVE 60H | 10 | 120 | 0,2 | 2 | 200 | 4 | 50 | 0,05 | 800 | hydraulic |

| 10 | 220 | 0,2 | 2 | 200 | 4 | 50 | 0,05 | 800 | hydraulic | |

| WVE 80 | 20 | 320 | 0,3 | 3 | 600 | 6 | 50 | 0,05 | 600 | hydraulic |

| 20 | 420 | 0,3 | 3 | 600 | 6 | 50 | 0,05 | 600 | hydraulic | |

| 20 | 420 | 0,3 | 4 | 800 | 6 | 50 | 0,05 | 200 | pneumatic | |

| WVE 120 | 30 | 420 | 0,5 | 6 | 2400 | 8 | 100 | 0,05 | 400 | hydraulic |

| 30 | 620 | 0,5 | 6 | 2400 | 8 | 100 | 0,05 | 400 | hydraulic | |

| 30 | 820 | 0,5 | 6 | 2400 | 8 | 100 | 0,05 | 350 | hydraulic | |

| 30 | 1020 | 0,5 | 6 | 2400 | 8 | 100 | 0,05 | 350 | hydraulic | |

| WVE 160 | 50 | 420 | 1 | 8 | 3200 | 10 | 100 | 0,05 | 400 | hydraulic |

| 50 | 620 | 1 | 8 | 3200 | 10 | 100 | 0,05 | 350 | hydraulic | |

| 50 | 820 | 1 | 8 | 3200 | 10 | 100 | 0,05 | 300 | hydraulic | |

| 50 | 1020 | 1 | 8 | 3200 | 10 | 100 | 0,05 | 250 | hydraulic | |

| 50 | 1520 | 1 | 8 | 3200 | 10 | 100 | 0,05 | 200 | hydraulic |